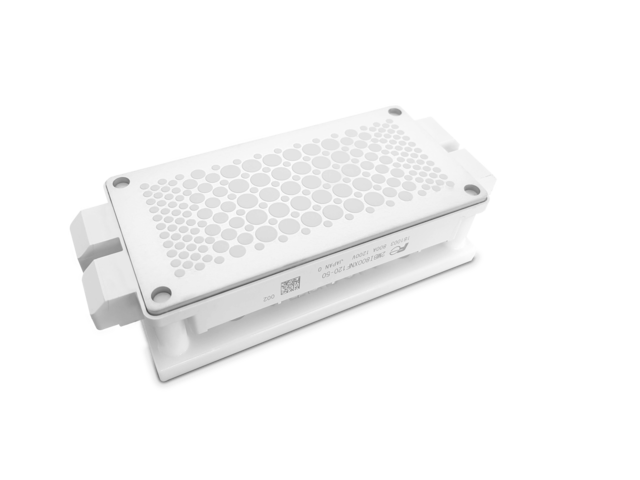

Thermal interface material (TIM)

Service for thermal interface material (TIM)

Fuji Electric’s automated printing process ensures consistent printing and improved thermal conductivity through precise printing equipment, optimized module-specific printing patterns and software monitoring. The printing process of pre-applied TIM is carried out by a computer-controlled printing line under clean conditions.

3D imaging checks ensure compliance with our specified TIM thickness and the whole process is controlled by our traceability system and qualified staff to ensure our quality standards.

Features

- Optimized pattern for Fuji modules

- Increased service life of the IGBT

- Extended IGBT power density

- New TIM: Higher thermal conductivity, suitable for Tc up to 150 °C, highly reliable

Process benefits:

- Outsourcing of a dirty process

- Stable quality level

- Increased system reliability

Thermal benefits:

- Higher thermal conductivity

- Uniform thermal resistance

- Higher reliability and lifetime

Get in contact

Our experts will answer any further questions you have about Fuji Electric and our technologies.